Spring 2020 Newsletter

Shop Updates

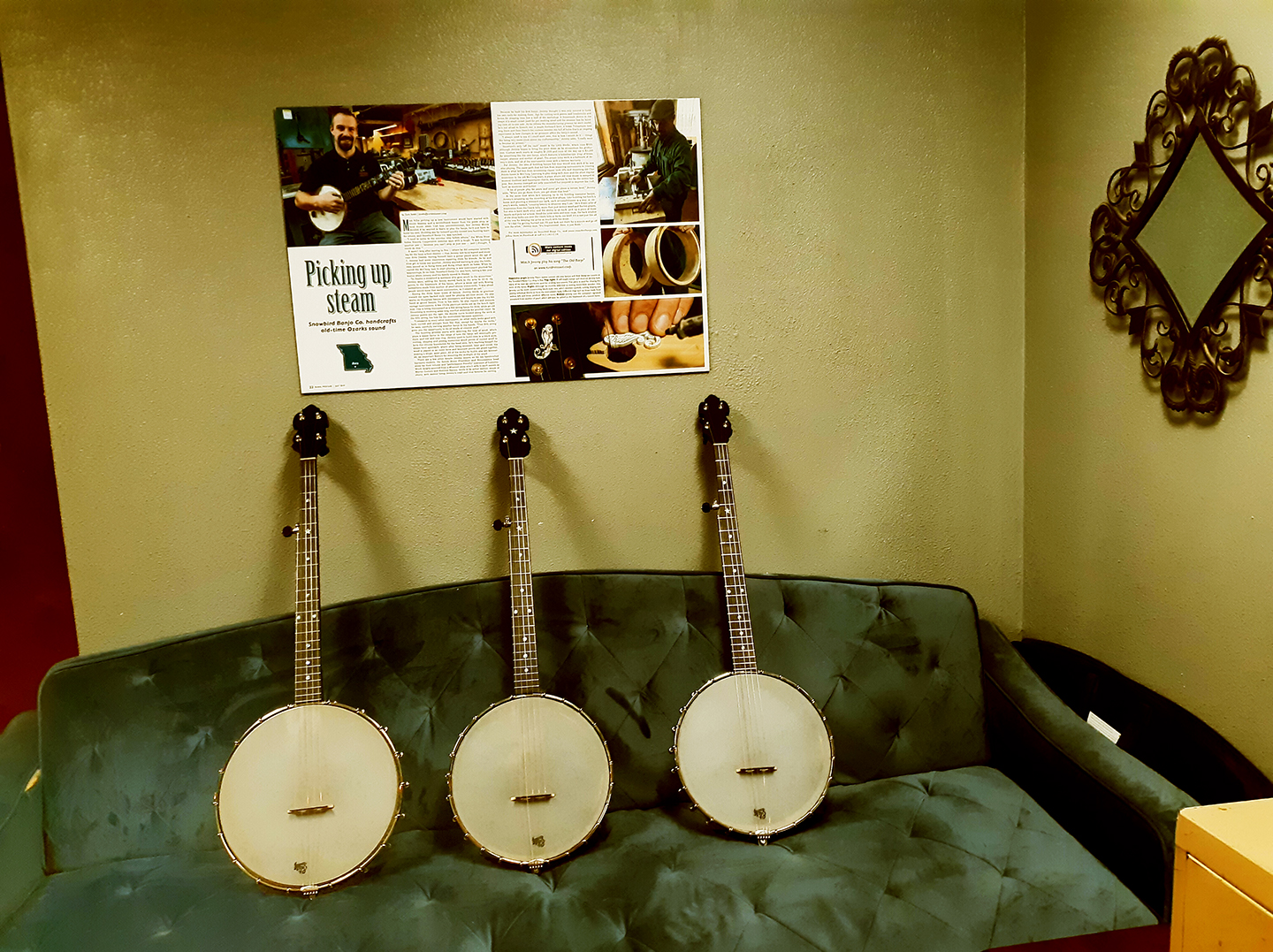

Between the end of 2019 and the start of 2020, we finished up 3 new Little Birdies and began to work on a couple custom banjos. In summarizing the year 2019, we tripled the number of banjos we produced and we built the needed jigs and components to make steam bent rims and make them efficiently. Everything to produce large batches of rims has been completed with the exception of acquiring a few more clamps.

I find it pretty amazing how when I am working it feels like I’ve made no progress, but when I look back at what I could not do last year, its astonishing to see what we’ve accomplished in just one year’s time.

Jeremy Myers

Much of the work for neck fabrication has also been streamlined with many jigs having been made for use on shaper equipment. There is one more jig that needs to be done to complete this ease of building, and that has been put off in favor of just getting more banjos built. It takes more time, but rather than devote an entire week or month to developing this jig, we can get some banjos out there right away.

An additional update to the business, we have added ducting for a permanent dust collector, even though the dust collector has not been purchased. That’ll take quite a few more banjos, in the mean time, We’ll continue using the ol’ cumbersome shopvac.

Website updates

The Snowbird Banjo website received a little face-lift this year. We have attempted to put everything in an easy to find location right on the front page. There may be future updates coming with the layout and features of the site but that will require a major overhaul if we do pursuit a change.

I’ve got a few ideas I’m working on to help in the process of ordering, more on that later.

Jeremy Myers

Facebook Group

An additional feature we’ve done, we created a Facebook group for Snowbird Banjo Customers! Whether you purchased a new banjo, or had an instrument of any kind repaired, we’d love to have you join the Facebook group. This group is to communicate about any issues with an instrument, learn more about the instrument, or just have a place to post a picture or video of you playing your Snowbird Banjo!

Design Change

Snowbird Banjo Company now is working towards sustainable sourcing of materials for our banjos. Going forward into the new year, we will be switching our Little Birdie banjos fretboard and trim wood from endangered and exotic Ebony over to Richlite which is a manufactured wood for music instruments. Many of the custom banjos will continue to use exotic woods such as ebony unless specifically requested, but we feel this move is positive step to slow the loss of the wonderful Ebony wood. We are also working towards a natural alternative for ebony for our everyday production that can be sourced locally.

The primary difficulty is that our Missouri woods do not offer a black type wood that is durable enough for a fretboard. Some options include Persimmon which is in the family of Ebony but its light color is not really suitable for our builds because it shows up dirt and its overall appearance is not part of our style. That said, some future research into dying these types of woods is ongoing, but the final product must be colored thoroughly so that cutting does not reveal the lighter wood beneath.

We’re excited for this new year and the opportunities that will present themselves. For more on our daily activities, check out our regular Facebook page, as well as Subscribe to our YouTube channel (don’t forget the click the bell beside the Subscribe button) to hear our banjos, we’re also on Instagram, and don’t forget to Subscribe to these newsletter updates.

Jeremy describes himself as an autodidact, multi-Instrumentalist, singer/songwriter, banjo builder, beekeeper, and a family man!